Tel: +86-136-7151-8833 E-mail: china@johnsonslot.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Imagine that the "heart" of a water well isn't the pump, but that unassuming well screen. Its entire life is a battle against two things: getting cloggedand succumbing to corrosion. Traditional perforated pipes are gradually being replaced precisely because they often fail these two challenges.

1. The Anti-Blinding Mystery: Fluid Dynamics Hidden in the "V" Shape

Result: This self-cleaning characteristic significantly reduces the risk of screen blinding, ensures sustainable water yield, and minimizes maintenance costs from frequent backwashing.

2. The Art of Balancing Strength & Flow: The Structural Aesthetics Behind High Open Area

Another core metric for a well screen is its open area (porosity)—the percentage of the screen's surface area dedicated to filtration. The open area directly determines the well's output efficiency.

Traditional Perforated Pipe: To increase the open area, more holes must be drilled. But this is like punching many holes in a steel plate, significantly compromising the pipe's overall strength.

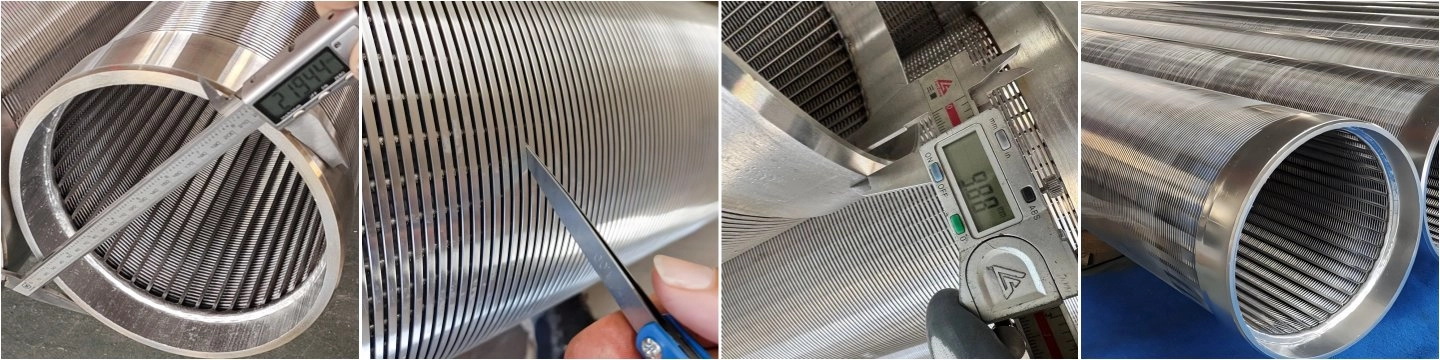

Wedge Wire Screen: By precisely winding the V-shaped wires around sturdy longitudinal support rods and welding them, a continuous, uniform slot networkis formed. This structure provides an extremely high open area (often over 30%) while its fully welded skeleton offers crushing and torsional strength far superior to perforated pipes, enabling it to withstand immense geological pressures without deforming.

3. The Material Dialogue: It's More Than Just "Stainless Steel"

When you choose "stainless steel," the story is just beginning. Groundwater environments are complex and can be rich in corrosive elements like chlorides and hydrogen sulfide.

SS304: Economical and versatile, but still at risk of pitting corrosion in water with high chloride content.

SS316/316L: With added molybdenum, its resistance to chloride corrosion is significantly enhanced, making it the better choice for most demanding environments.

Duplex Steel: For extremely corrosive environments or high-strength requirements, it is the ultimate solution.

A professional choice isn't about selecting the most expensive option, but the most correct one.A responsible supplier will ask for your water analysis report, not just quote a price.

Initial Cost: Wedge Wire Screen > Perforated Pipe.

Maintenance Cost: Wedge Wire Screen (minimal maintenance) << Perforated Pipe (frequent cleaning, replacement).

Well Lifespan & Efficiency: Well lifespan and stable yield ensured by Wedge Wire Screen >> Perforated Pipe.

A good well begins with a good screen. Its value lies not in the steel itself, but in the profound understanding of fluid dynamics, material science, and structural mechanics behind it. Choosing it means choosing long-term reliability and efficiency for your valuable water resource project.