A:

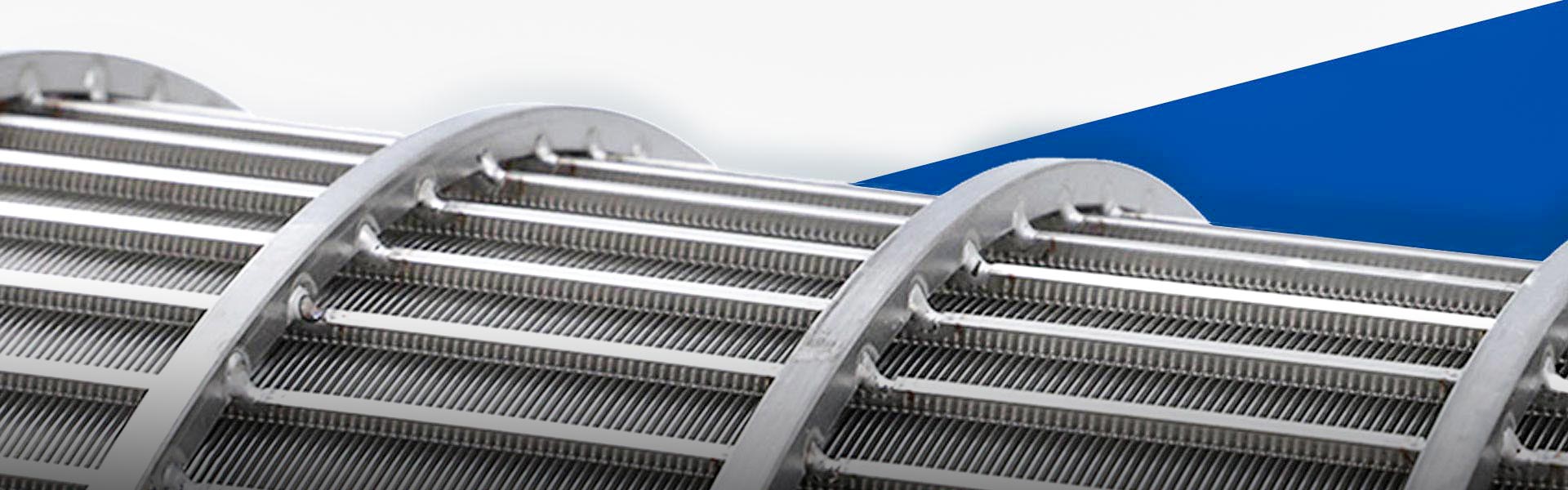

Wedge Screen is mainly made of stainless steel (304/316L), Hazelloy, titanium alloy and polypropylene (PP/PVDF) and other materials, its all-welded structure ensures high stability, V-shaped wedge wire design combined with material characteristics, to achieve anti-blockage, self-cleaning and health safety. Meet the diversified needs of industrial filtration for temperature resistance (-200℃ to 550℃), pressure resistance (above 30MPa) and precision separation.