Appropriate Slot Sizes Selection of Wedge Wire Screens

The slot size refers to the width of the openings or slots between the V-shaped wires on the wedge wire screen.This parameter is crucial for filtration. It is typically measured in microns (μm) or millimeters (mm).

Determine the specific requirements of your application. It affects the material and slot size selection and you should know the following conditions:

- What type of material or particles do you need to filter or separate?

- What is the desired flow rate?

- What are the temperature and pressure conditions?

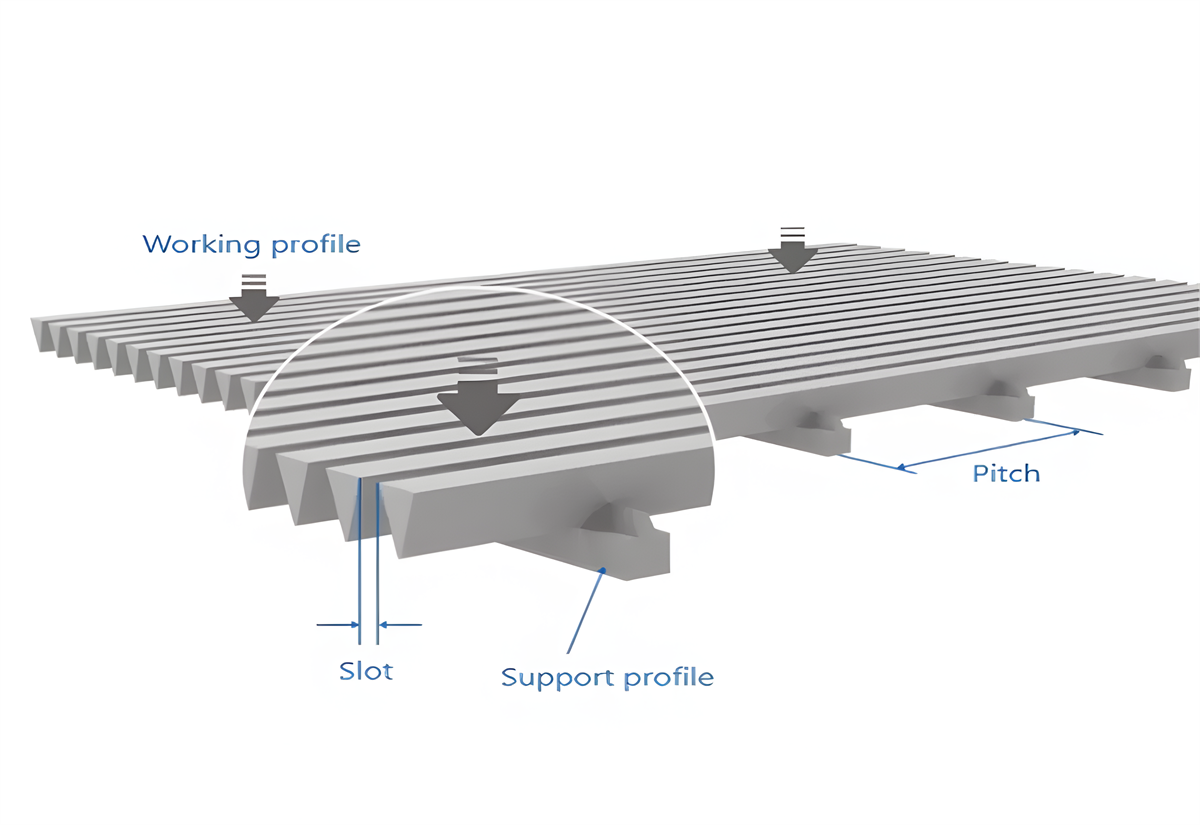

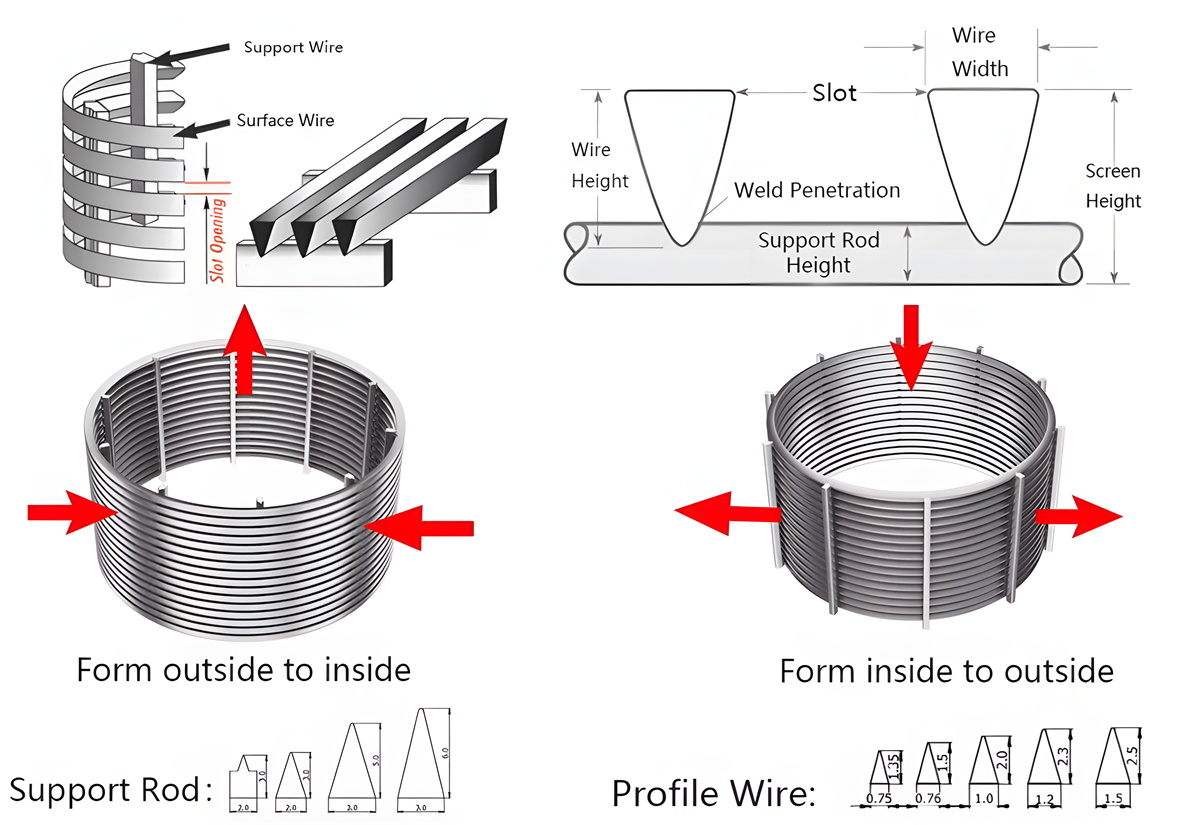

Select Right Surface & Support Profiles

Selecting suitable profile wires and support rods for wedge wire screens needs careful thought. Key factors to think about are the application, materials, desired filtration, and structure. Follow these steps to pick the right profiles:

- Determine whether it's for filtration, separation, sizing, dewatering, or another application.

- Confirm filtration solution characteristics

- Define filtration requirements

- Consult with our specialists

Selecting the right material grade for wedge wire screen

Selecting the right material grade for wedge wire screens is crucial for optimal performance and longevity in industrial processes.

Consider factors like operating environment, abrasion resistance, chemical compatibility, and cost to meet application needs. We list key material selection factors and discuss commonly used materials.

- Temperature

- Abrasion Resistance

- Chemical Compatibility

- Strength and Durability

- Cost Considerations

How to Quickly Select the Appropriate Wedge Wire Specifications?

- Slot Sizes

Slot size: 20 micron to 3000 micron(Tolerance:±5 micron),etc.

- Diameter

Our wedge wire screen diameter ranges from 1" to 48". You can choose corresponding screen diameter according to your specific application requirements.

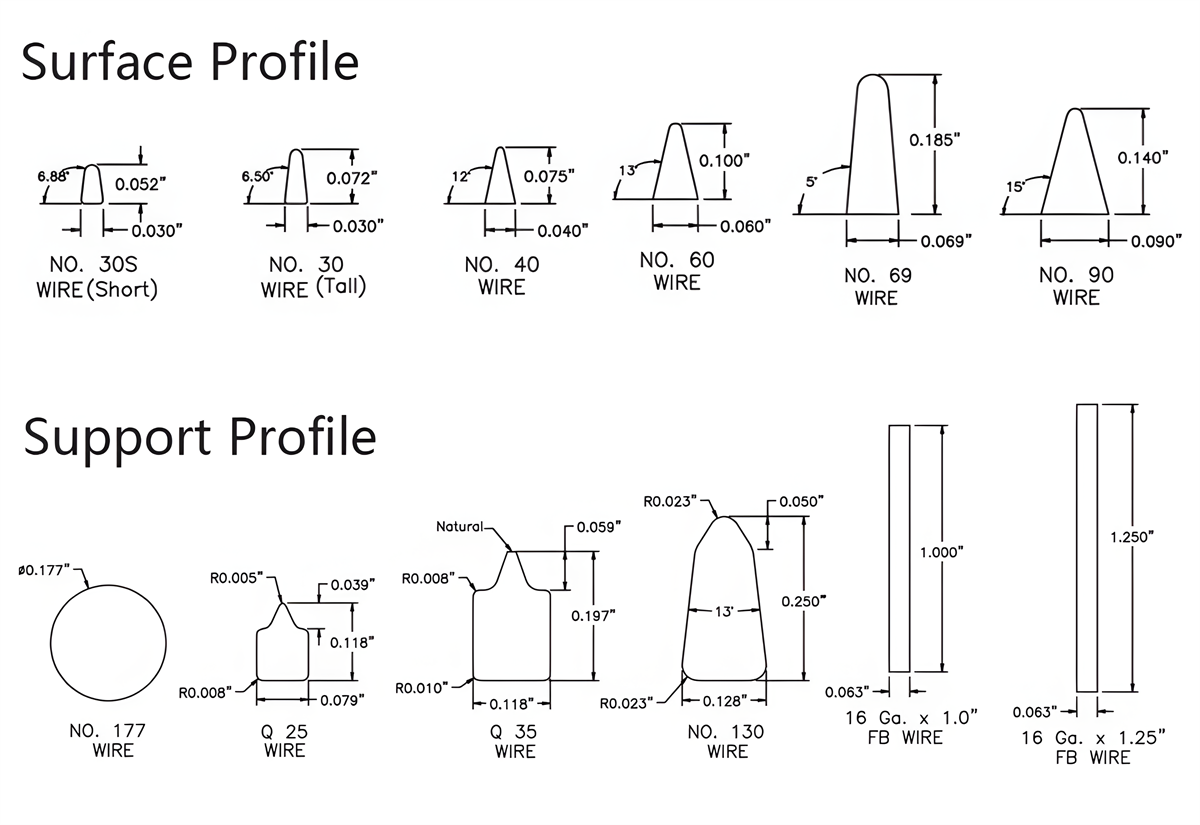

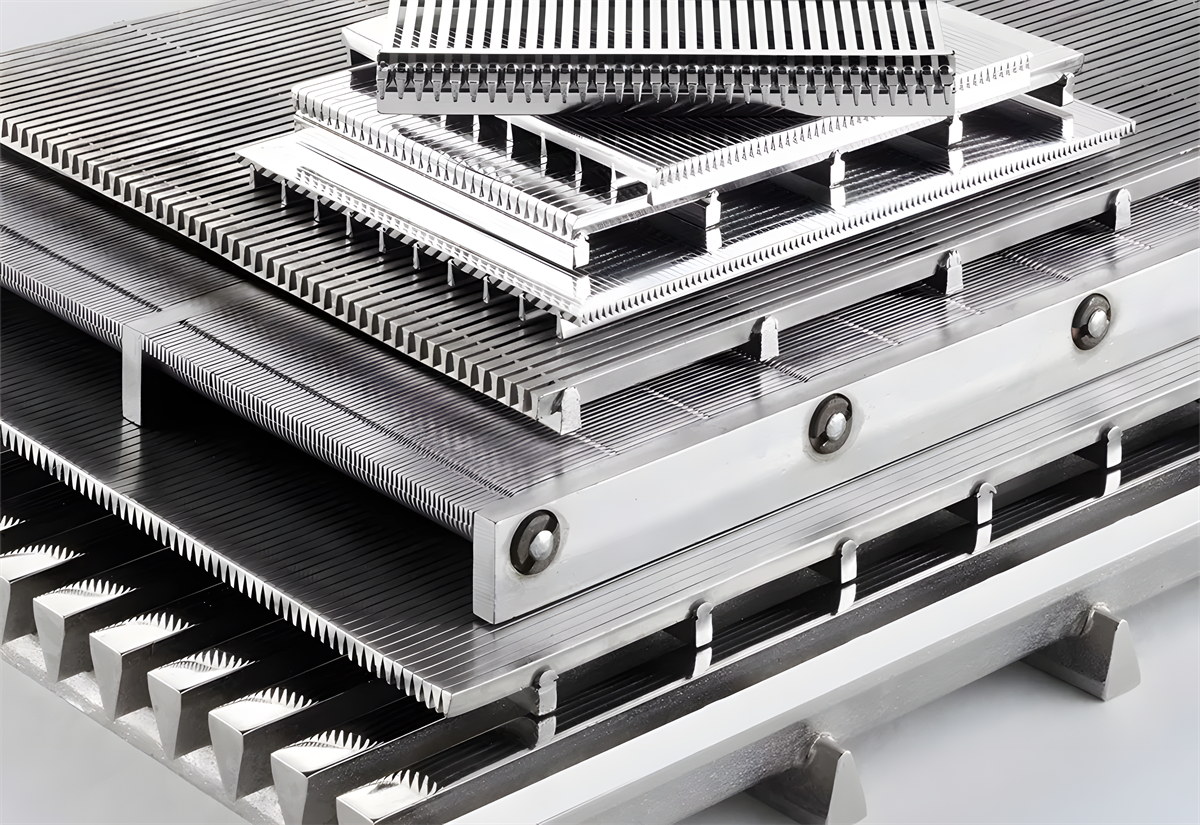

- Construction Profiles

We offer various surface profile wires and support rods, enabling custom screen designs per technical or structural specifications.

- Filter direction

Surface profiles and support profiles determine filtering flow direction. Wedge wire tubes are either FOTI or FITO.

Keep in touch with us

Mob:+86-136-7151-8833

E-mail: china@johnsonslot.com