INDUSTRIAL-GRADE POLYURETHANE SCREENS

· 300% Longer Lifespan Than Steel Mesh

· 35% Higher Screening Efficiency

· ISO 9001 and SGS safety dual certification guarantee

Application Scope of Polyurethane Elastomers

Coal Preparation, Mining & Metallurgy Industries

Products: Screen panels, rubber rollers, tires

Features:Wear resistance, water resistance, oil resistance, vibration damping & noise reduction, high strength, strong adhesion to metal frames, low noise, effective self-cleaning, reduced screen machine load, energy savings, extended screen life, high screening quality.

Coatings, Footwear, and Potting/Repair Materials

Polyurethane offers excellent cushioning and wear resistance, so microcellular elastomers are primarily used for footwear. Polyurea elastomers are used for coatings, potting, and repair materials.

Medical Applications

Due to high strength, wear resistance, biocompatibility, and absence of plasticizers and other small-molecule inert additives, it holds significant importance in medical polymer materials. Examples: Gastroscope tubes, medical catheters, bandages, tracheal cannulas, artificial hearts, pacemakers, heart valves.

Mechanical Components

Polyurethane seals exhibit superior mechanical properties. They outperform other rubbers in wear and high-pressure resistance, with excellent aging/ozone/oil resistance. Primarily used for:

Piston rod seals in heavy-duty mobile machinery/industrial hydraulics

Vibration dampers

Connecting shafts

Polyurethane Screen Panel Advantages

Wide hardness range

Hardness adjustable range: Shore A0 to Shore D85,High load capacity at same hardness compared to other elastomers,Broad resilience range

Excellent Oil and Chemical Resistance

Polyurethane elastomers, especially polyester-based polyurethane elastomers, are strongly polar polymer materials. They exhibit low affinity with non-polar mineral oils, and are virtually unaffected in fuel oils (such as kerosene and gasoline) and mechanical oils (such as hydraulic oil, engine oil, lubricating oil), performing significantly superior to rubber.

Weathering and Oxidation Resistance

Polyurethane elastomers perform adequately in inert gases (such as nitrogen). Generally, polyurethane elastomers have a continuous service temperature range of -45°C to 90°C in air, with short-term exposure up to 120°C. At ambient temperatures, they exhibit excellent resistance to oxidation and ozone.

Comparison with Other Materials

Compared to metals

Lighter weight

Lower noise, Wear resistance

Lower processing costs

Corrosion resistance

Compared to plastics

No brittleness

Good elasticity

Abrasion resistance

Compared to rubber

Superior wear resistance, Cut resistance

Tear resistance, Transparency

Ozone resistance, Castable

Potting suitability, Wide hardness range

Application Scope of Polyurethane Elastomers

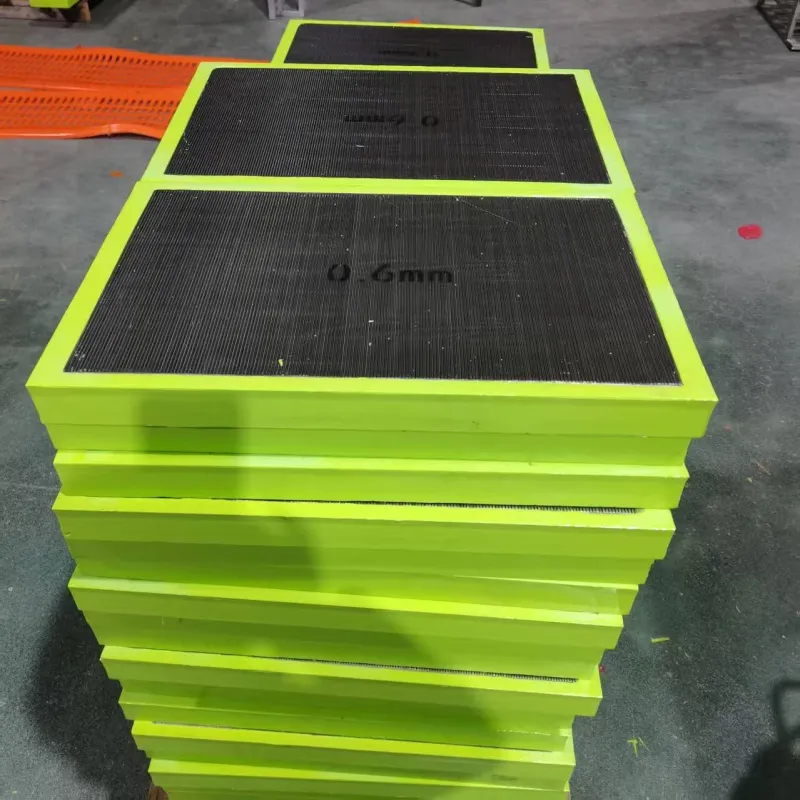

Polyurethane Tension Screen

Polyurethane Edging Sieve Plate

Self-cleaning screen

Polyurethane Fine Mesh

Tensioned polyurethane fine screen meshes (sometimes referred to as polyurethane high frequency screen mesh) are made of polyurethane sheet with high density opennings.

MDI Flip-Flow Screen Panel

Polyurethane Modular Panel

Polyurethane modular screen panels are vital elements of vibrating screens, crafted from specially formulated polyurethane. These panels are meticulously cast and injected...

Analysis Application Case

A Coal Washing Plant in China

After adopting high-efficiency self-cleaning screen panels, the original design's 25mm separation size was reduced to 13mm. Statistics show:

1.Annual clean coal output increased by 452,000 tons;

2.Commercial coal calorific value improvement:

For 43 raw coal (13-25mm): +2,305.15 Kcal/kg per ton;

Overall 43 coal: +296.15 Kcal/kg;

Blended 43 & 52 commercial coal: +62.9 Kcal/kg;

3.Annual profit: RMB 41,297,500;

4.Cost savings:

Throughput of 43 coal increased from 1,200 t/h to 2,000 t/h;

Daily production time reduced by 2.8 hours, decreasing equipment wear and saving electricity consumption;

Annual electricity cost savings: RMB 1,520,000.

Note: Current screen aperture size at this plant: 8mm

Why Choose Us

SLOT has over 15 years of experience in manufacturing well screens, with our specialized engineers, skilled workers and advanced production equipment.We can always provides customized service with a wide range of materials,slot sizes, lengths, diameters of well screens. We will assist you to design the most perfect solution for your special needs.

Manufacture and sell.SLOT have more than ten production equipment and 5 production lines,With imported fully automated computer numerical control equipment,Germany technology and advanced Inspection methods, SLOT has developWed more than 20 kinds of filtering products, the appearance and accuracy of which have a leading level at home and abroad.

Keep in touch with us

Mob:+86-136-7151-8833

E-mail: china@johnsonslot.com